PYRAMID® AND PYRAMID PLUS™ SCREENS (PMD® & PMD+™)

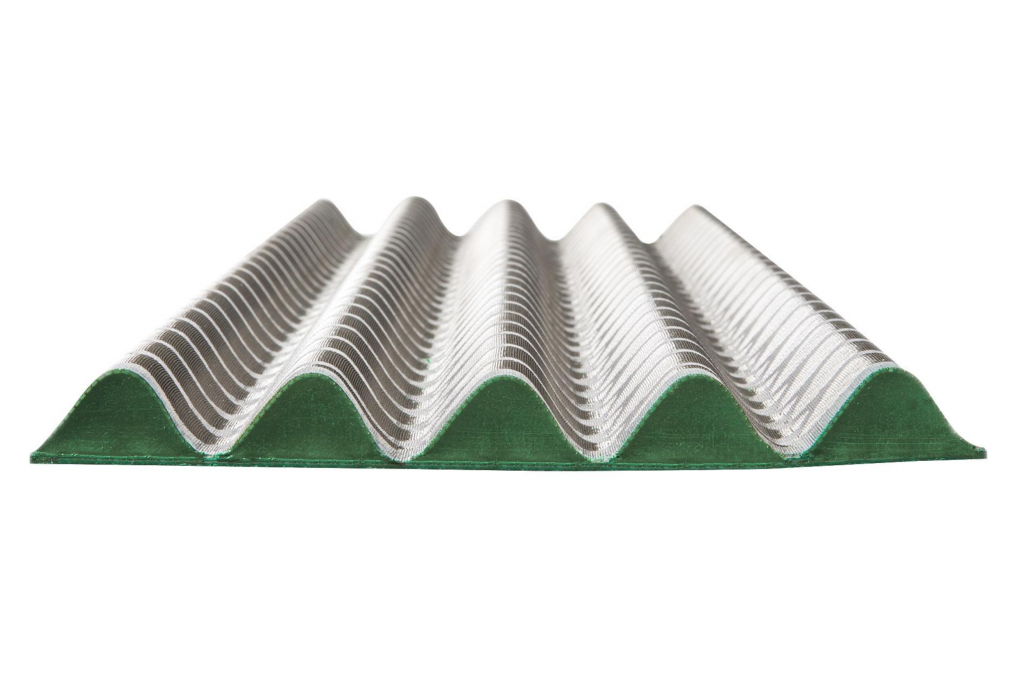

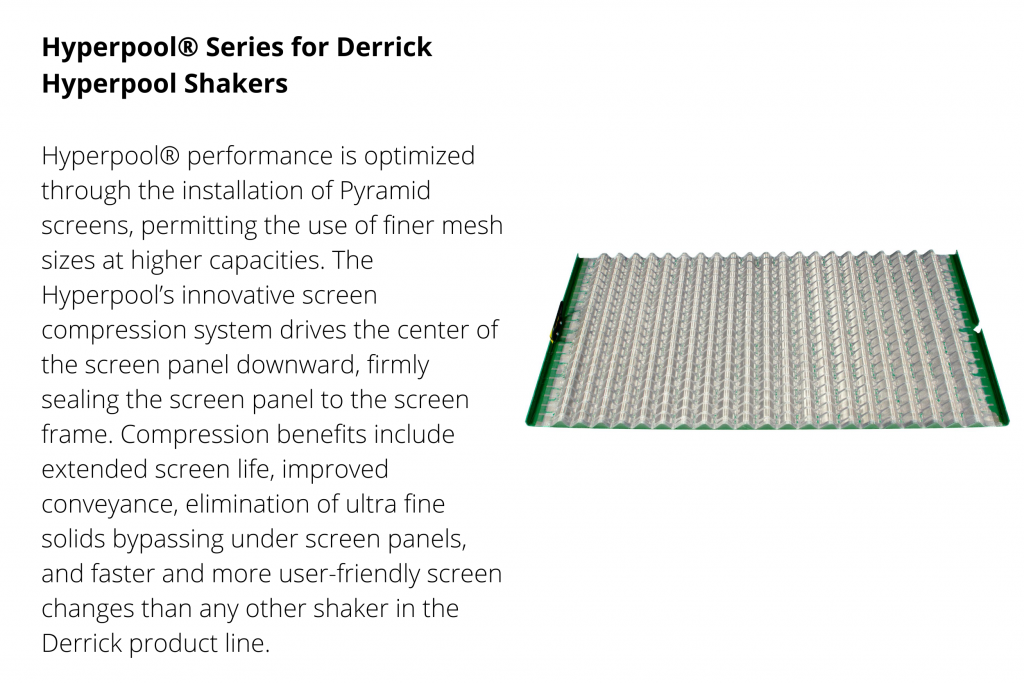

Derrick has revolutionized screening technology with the patented Pyramid® (PMD®) and Pyramid Plus™(PMD+™) screens. These revolutionary three-dimensional screens offer the benefits of traditional flat multi-layered screens while adding a significant increase in usable screen area. The result is a screen that increases fluid handling capacity. Pyramid and Pyramid Plus screens provide an easy, cost effective increase in shaker performance. Designed with the latest technology, Pyramid screens allow rigs to screen finer earlier in the drilling process, thus significantly reducing mud and disposal costs. All Derrick screens are API RP 13C compliant.

- Increased Shaker Capacity

- Makes Fine Separations

- Fits Existing Shakers

- Screen Finer Faster

- Drier Cuttings

SCREEN SHAPE AND CONDUCTANCE

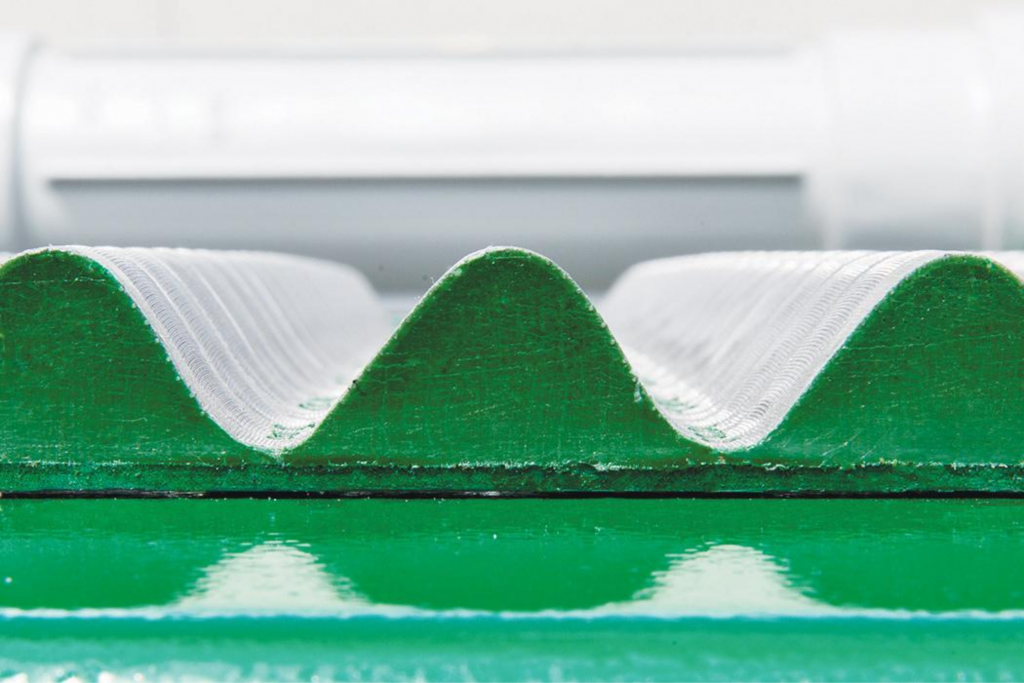

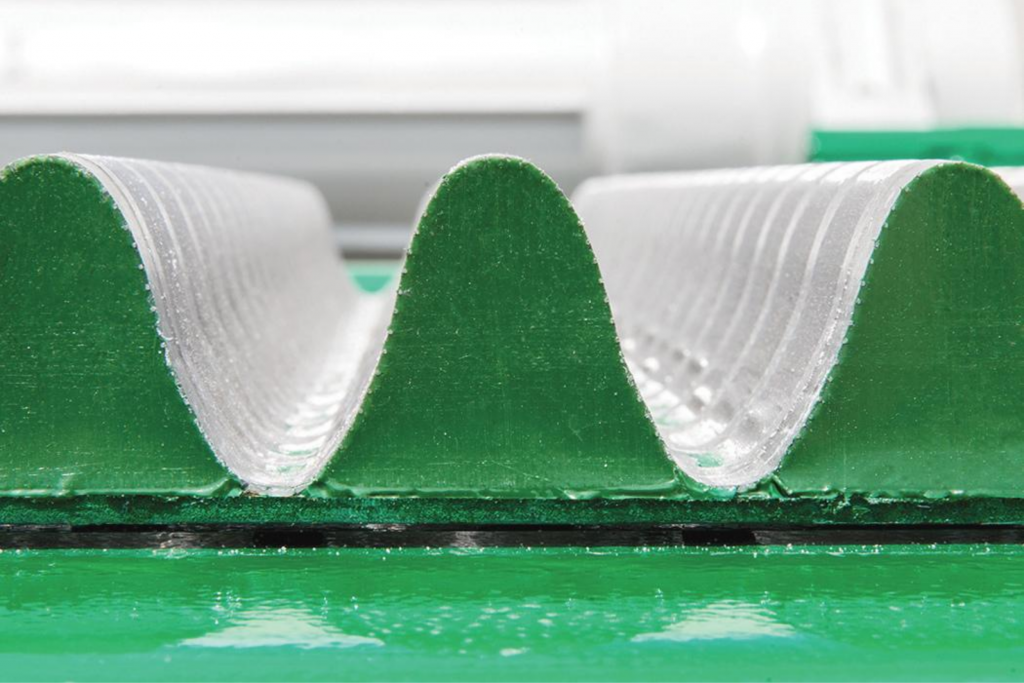

ENHANCED PERMEABILITY

Gravity and vibration force the solids into the corrugated screen’s troughs,

thus allowing more fluid to pass through the top of the screen

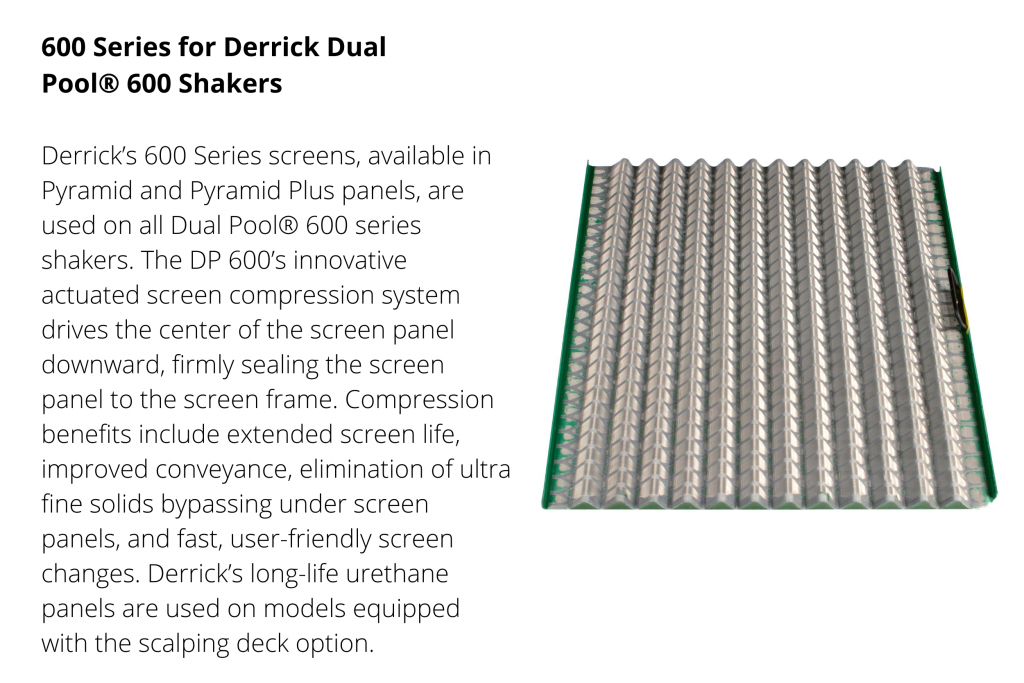

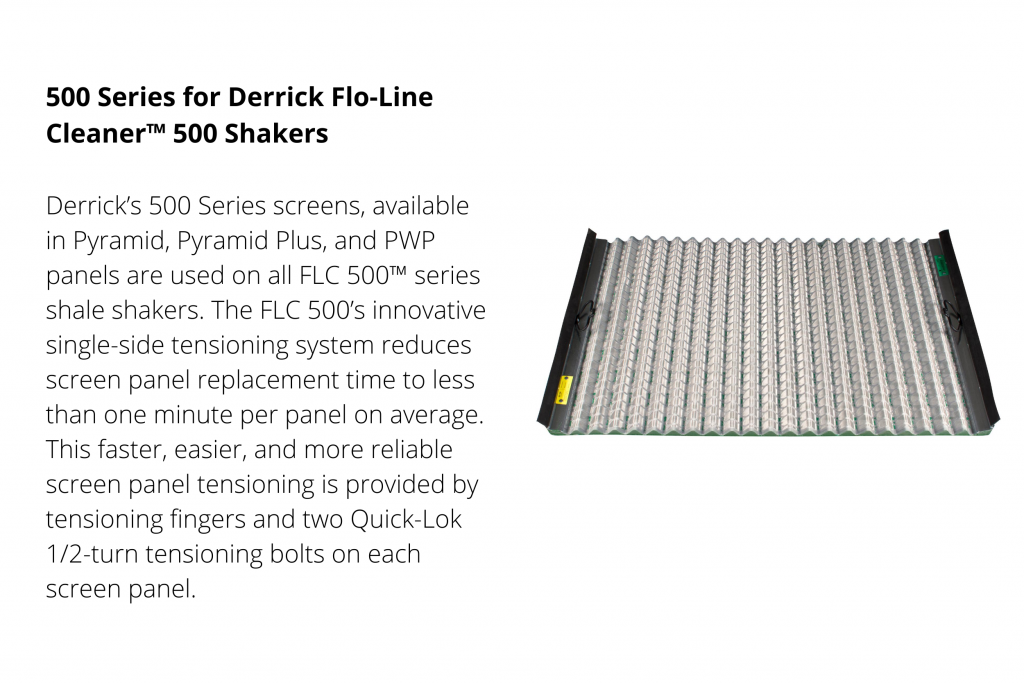

REPLACEMENT SCREEN PANELS FOR DERRICK SHAKERS

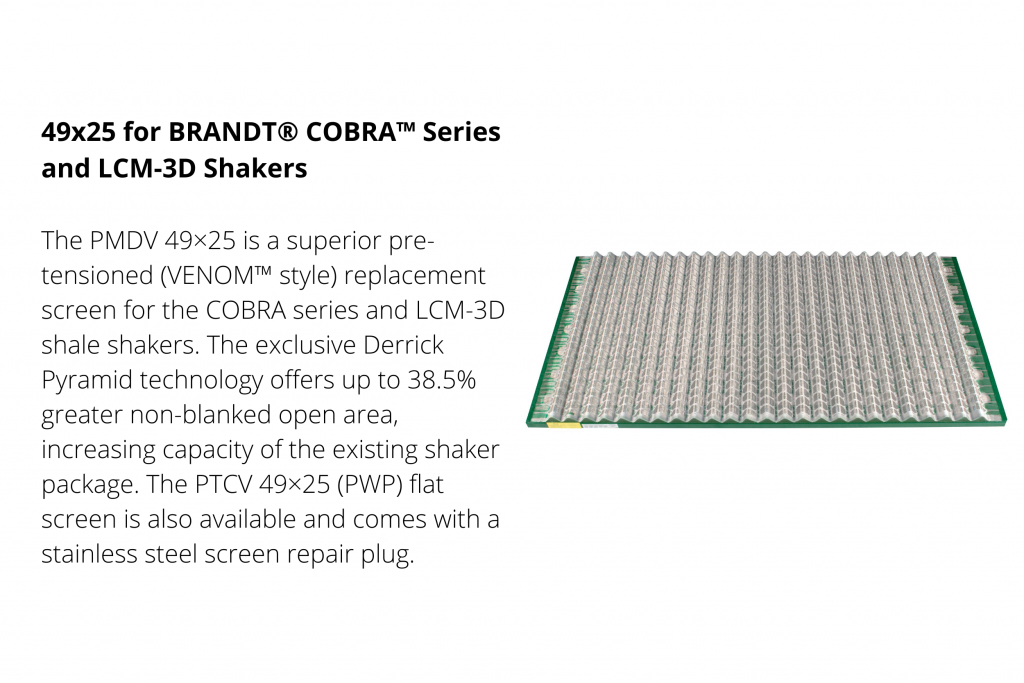

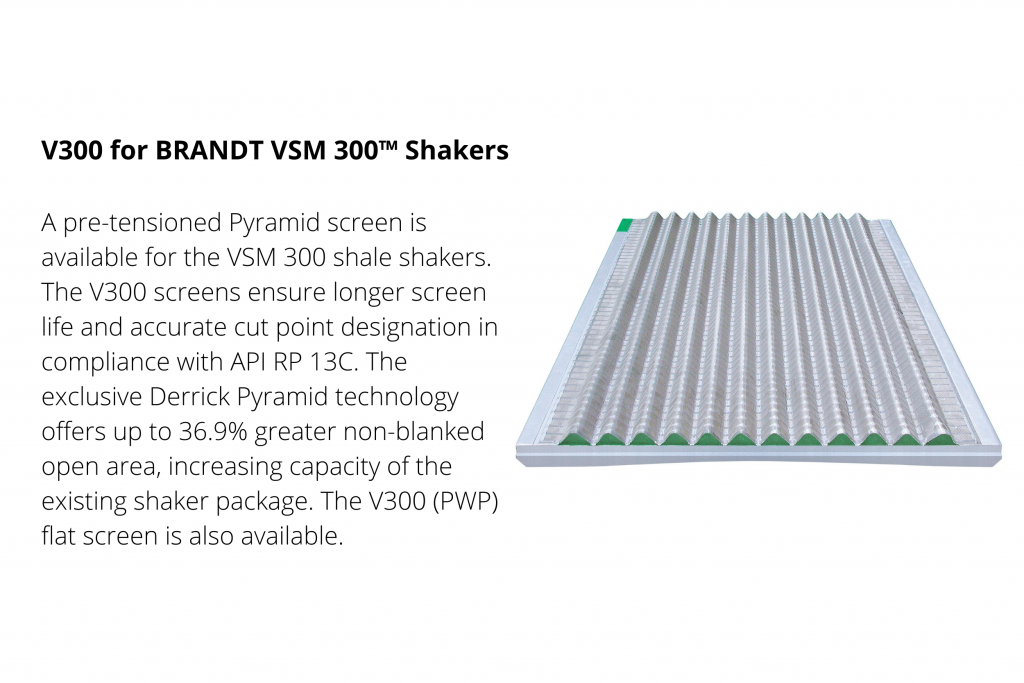

REPLACEMENT SCREEN PANELS FOR NON-DERRICK SHAKERS

BRANDT, COBRA, KING COBRA, VENOM, and VSM 300 are trademarks and/or registered trademarks of National Oilwell Varco. M-I SWACO, MONGOOSE, and MEERKAT are trademarks and/or registered trademarks of M-I L.L.C..

FEATURES & BENEFITS

MAKES FINE SEPARATIONS

- Pyramid and Pyramid Plus screens are capable of making separations as fine as 40 microns.

FITS EXISTING SHAKERS

- Pyramid screens fit all Derrick shakers, thus allowing for the most efficient use of existing equipment. There is no need to modify or replace the existing shaker.

SCREEN FINER SHAKERS

- Utilizing Pyramid or Pyramid Plus screens enable shakers to screen 1 to 2 API sizes finer than traditional perforated plate flat screen panels. This maximizes the solids removal efficiency of the shaker.

DRIER CUTTINGS

- Pyramid screens minimize fluid loss by dispersing thinner layers of fluid over an increased screen area, resulting in a more effective and faster drying capability.

RELATED DOCUMENTS

FILE REPORTS

Please note: Information on this website is subject to change. To obtain accurate dimensions and equipment configurations, please contact the Derrick Engineering Department for an updated GA drawing.

Añadir email lock